SainSmart Genmitsu 3018-MX3: Review the Specs

https://all3dp.com/1/sainsmart-genmitsu-3018-mx3-review-the-specs/

Once an industrial technology that was only used by machine and fabrication shops, manufacturing houses, and similar industrial settings, CNC machinery has matured over the years, allowing for mass adoption at the garage level.

Whether you are cutting jigs and fixtures to aid other processes or making a custom wooden sign for fun, a CNC router is a versatile workshop tool. As the technology has matured and become prolific, several OEMs have driven prices down and opened CNC up to budget-conscious consumers.

One such OEM is SainSmart, which emphasizes its #PowerToTheMakers slogan throughout its maker-centric product lines, which includes CNC, Arduino kits, Raspberry Pi, and more.

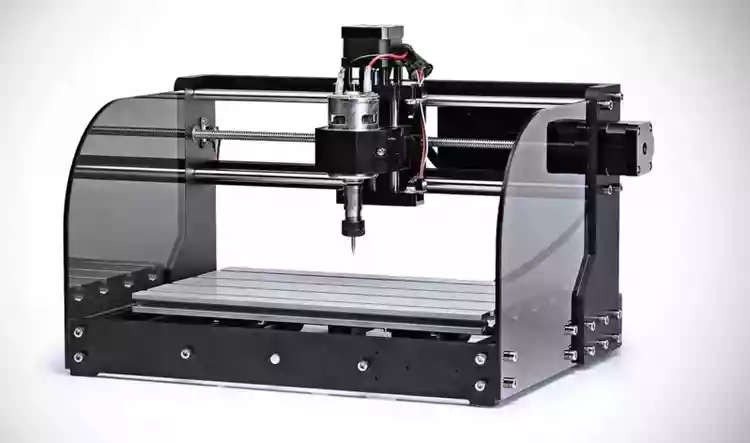

Low cost and versatile, SainSmart’s Genmitsu 3018-MX3 appears to serve as a multi-function tool that undoubtedly would find a use for crafters and makers looking to start a business. At ~$300, the economical price point for this machine is a low target for achieving ROI.

Anyone with an intermediate skillset for CNC can benefit greatly from having a versatile machine that can handle a variety of materials, plus the end mill sizes to create 2D pieces with minimal setup and operation time. SAINSMART GENMITSU 3018-MX3: REVIEW THE SPECS Features There are four different models of SainSmart’s popular Genmitsu 3018 range, all of which are spec’d a little bit differently from one another. The 3018-MX3 sits on the upper end of the spectrum, offering a higher RPM spindle, upgraded PCB controller, and acrylic shielding.

Coming in at ~$350, approximately $100 more than the base model, the MX3 provides a higher degree of features and functionality, not least of which is its compatibility with Mach3 industrial controller software, and auto tool zeroing.

ENGRAVING

The Genmitsu 3018-MX3 carries full 3-axis capability and has a 300 x 180 mm working area, 7000 RPM spindle, and a durable chassis. Occupying a spot on the market as a low volume, high mix-type of machine for a variety of different materials, the MX3 has the benefit of being tidier to run than most other Genmitsu machines thanks to the acrylic siding, which allow for partial chip containment and should make it easy to clean after long runs.

MATERIALS

Plastic, soft metals, and wood are among the primary materials the MX3 is capable of. With a large working area, having limit switches as standard helps prevent mechanical damage from the chassis of the machine.

JOB SETUP

Standard T-Slot tables are typical for hobbyist-level desktop machines but serve as a quick mechanism for changing out fixtures with reasonably minimal effort. With a standard ER-11 collet setup, the end-user has immense flexibility in terms of different sized tools for various types of cutting applications. You can also have an easy time decreasing setup times by making use of the touch probing system for setting the Z height. All things considered, there appears to be tremendous value packed into this machine.

MACH3

While pricey, Mach3 does offer a variety of canned cycles for 3-axis cutting, including drilling, engraving, milling, and general-purpose light duty machining, and importing DXF files is fairly straight forward, with overall setup time minimal for simple 2D pieces. This is an Arduino based program with support, online tutorials, and training, plus other helpful guides to help you program your CNC. Mach3 CAM Software – although unique among Genmitsu machines – is not your only option for controlling the MX3; the MX3 also plays nicely with the free DrufelCNC software.

GRBL COMPATIBILITY

It is also important to note that there are open source platforms such as GRBL, which SainSmart recommends for those not wanting to purchase an industrial software package for the MX3 (which somewhat defeats the point of buying the MX3). Those committed to this path will have to buy a different board (SainSmart’s PROVer, or a third party alternative) before the MX3 cooperates with GRBL.

SAINSMART GENMITSU 3018-MX3: REVIEW THE SPECS Specs

-

Assembly: Semi-assembled

-

Frame: Aluminum, phenolic resin

-

Cutting area: 260 x 155 x 35 mm

-

Control software: Mach3

-

Advertised assembly time: ~2 hours

-

Machine footprint: 400 x 330 x 240mm

-

Spindle: 775 motor, ~9000 RPM

-

Rated power: 60W

-

Maximum power: 120W

-

Step Motor: 1.3 A, 12V, 0.25 Nm torque (2.2 in-lb)

-

End Mill: ER11 collet; tip 0.1 mm, 20 degrees, diameter 3.175 mm

-

OS: Windows XP, Windows 7 32/64 bits, Windows 8, Windows 10

-

Power Supply: 24V/4.75A